Top Features to Look for in 3D Print Design Software

Choosing the right 3D print design software is crucial for anyone involved in 3D printing. The market offers a plethora of tools catering to various expertise levels and project requirements. With suc...

23/01/2025

Choosing the right 3D print design software is crucial for anyone involved in 3D printing. The market offers a plethora of tools catering to various expertise levels and project requirements. With such diverse options, it’s essential to know the top features that distinguish excellent 3d print design software from the rest. From user interface to advanced modeling tools, understanding these features helps ensure that your creative visions are efficiently realized into high-quality 3D prints.

What Are the Essential Features of 3D Print Design Software?

When navigating the options in 3D print design software, certain core features can significantly impact your experience and output quality.

User-Friendly Interface

A user-friendly interface is essential for both beginners and experienced professionals. Software like Morphi stands out for its intuitive, touch-based design, making it accessible to users of all skill levels. This simple, approachable interface allows you to focus on creativity and innovation without getting overwhelmed by complicated controls, ensuring a seamless and enjoyable 3D design experience for everyone.

Compatibility with File Formats

Versatility in file format compatibility is crucial for a smooth workflow. Software like SelfCAD supports multiple file formats, ensuring seamless integration with various 3D printers and design tools. This flexibility helps streamline the design process, saving time and reducing frustration. By enabling easy file sharing and compatibility, it ensures your workflow remains efficient and uninterrupted, making the overall 3D printing experience more productive.

Advanced Modeling Tools

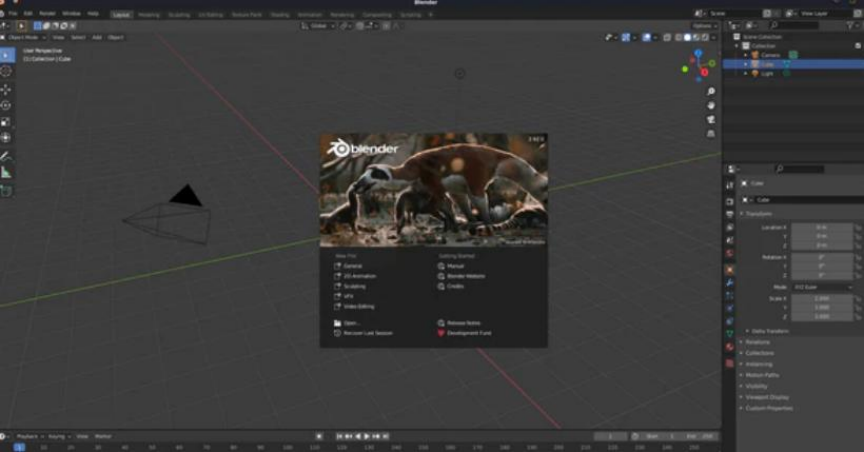

For those seeking precision and detailed designs, advanced modeling tools are essential. Blender, with its powerful design, sculpting, and simulation features, provides comprehensive capabilities for both simple and complex projects. These tools enable the creation of intricate, high-quality 3D models, ensuring that each project meets your specific needs with accuracy and attention to detail, making it an ideal choice for professional-level 3D modeling.

Why Accuracy and Precision Matter in 3D Print Design Software

Accuracy and precision are critical in 3D printing, impacting the final product’s quality and functionality.

Calibration and Measurement Tools

Effective calibration and measurement tools are essential for achieving high precision in 3D prints. Software like Meshmixer offers excellent tools for checking and adjusting mesh accuracy. These tools ensure that every detail, down to the smallest dimension, matches your design specifications, leading to better print quality and more reliable results. Proper calibration ensures that the 3D printer delivers the highest level of precision possible.

Minimizing Errors and Failures in Prints

Accurate software helps minimize errors and print failures. Features like Meshmixer's printability checks allow detailed assessment of potential issues before printing, saving materials, time, and effort. This predictive capability ensures that design problems are addressed upfront, reducing the risk of print failures and optimizing the overall printing process. By catching errors early, users can improve the quality and efficiency of their 3D prints.

Key Features for Optimizing 3D Print Speed and Efficiency

Speed and efficiency are vital for producing cost-effective and timely 3D prints without compromising on quality.

Print Settings and Customization

Customizing print settings is key to enhancing speed and efficiency. Tools like PrusaSlicer provide detailed control, enabling users to adjust parameters such as layer height and print speed. This flexibility allows you to fine-tune the balance between speed and print quality, ensuring optimal results tailored to your project’s specific needs and objectives. Fine-tuning these settings can lead to faster prints without compromising the final output.

Batch Processing and Automation

Batch processing and automation features enhance the print preparation process. SelfCAD’s integrated slicer allows multiple models to be processed simultaneously, streamlining workflow. This is particularly useful for large-scale projects or when multiple versions of a model are required quickly. With this capability, users can save time and boost productivity, making it an ideal solution for those managing numerous prints at once.

How to Choose the Right 3D Print Design Software for Your Needs?

Choosing the right software involves evaluating your skill level, project needs, and the materials you plan to use.

For Beginners vs. Advanced Users

Beginners can benefit from software with simpler interfaces, such as 3D Slash, which offers a fun, gamified experience perfect for newcomers. On the other hand, advanced users may prefer software like Blender or Fusion 360, which provide extensive features for creating intricate designs and tackling professional-grade projects, catering to more experienced 3D modelers and designers seeking greater control and precision.

Considerations for Different Printing Materials

The choice of software often depends on the materials you plan to use. Some software offers advanced settings tailored for specific materials, ensuring optimal print quality. For example, Ultimaker Cura provides detailed customization options for various filament types, helping enhance print durability and finish. This flexibility ensures better results, whether you're working with PLA, ABS, or more specialized materials.

Conclusion

Selecting the right 3D print design software hinges on understanding the features that align with your needs and goals. From user-friendliness and file compatibility to advanced modeling tools and accuracy features, each aspect plays a crucial role. Whether you are a beginner or a professional, prioritizing these features will help you create high-quality and precise 3D prints. Carefully evaluate your requirements and leverage the right tools to bring your creative visions to life efficiently and accurately.